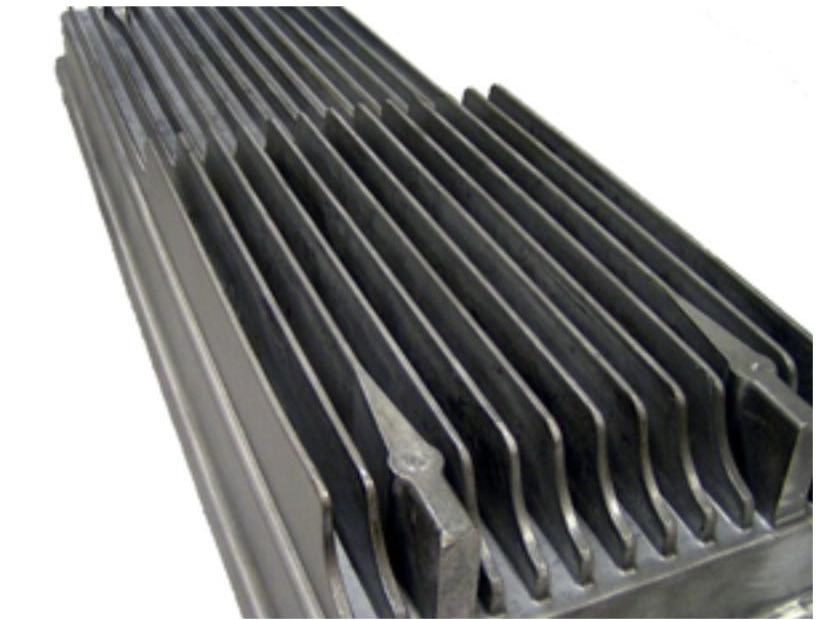

A telecommunications equipment manufacturer needed a large-format aluminum heat sink with exceptional dimensional stability for their high-performance networking equipment. The component required precise tolerances across its entire surface to ensure optimal thermal management in critical telecommunications infrastructure.

The Challenge

- Large casting requirements: The heat sink’s size pushed the boundaries of standard die casting capabilities

- Dimensional precision: Telecommunications applications demanded tight tolerances across the entire component

- Thermal performance: The heat sink design required consistent fin geometry and surface quality for optimal heat dissipation

- No existing solution: This was a completely custom application requiring a ground-up manufacturing approach

The customer needed a casting partner capable of producing large, dimensionally stable components that could meet the exact standards of telecommunications equipment. Solution: Glocon invested in advanced manufacturing capabilities specifically to meet this challenging requirement, implementing high-tonnage pressure die casting with precision process controls.

Our Approach

- Equipment Investment: Installed higher tonnage pressure die casting machines capable of handling large-format components

- Precision Process Controls: Implemented advanced process monitoring and control systems to maintain dimensional consistency

- Optimized Tooling Design: Engineered specialized tooling to ensure uniform material flow and consistent fin formation

- Quality Assurance: Established rigorous dimensional inspection protocols to verify tolerance compliance

Results

The high-tonnage pressure die casting approach delivered exceptional results for this demanding application:

- Achieved dimensional stability: Met all tolerance requirements across the large-format heat sink

- Consistent thermal performance: Uniform fin geometry and surface quality ensured optimal heat dissipation

- Scalable production: Established repeatable process capable of meeting ongoing production volumes

- Enhanced manufacturing capabilities: Expanded Glocon’s capacity to serve large-format, precision casting applications

Why This Matters

This project demonstrates Glocon’s commitment to investing in advanced capabilities to meet unique customer requirements. By implementing high-tonnage equipment and precision process controls, we successfully delivered a large-format casting solution that met the exacting standards of the telecommunications industry.